We are familiar with barcodes, which are everywhere. Barcodes became an essential tool for businesses to manage their inventory and track products as they move through the supply chain. This technology optimizes working processes for many businesses.

A barcode is a small image of bars and spaces that is a machine-readable representation of numerals and characters. It is affixed to retail store items, ID cards, and postal mail to identify a particular product number, person, or tracking number.

Barcode Components

Barcodes must be designed in a precise and uniform way so a barcode scanner can read and transmit the encoded data to a computer. Using various components, a barcode may also reveal the country of origin, product category, and manufacturer.

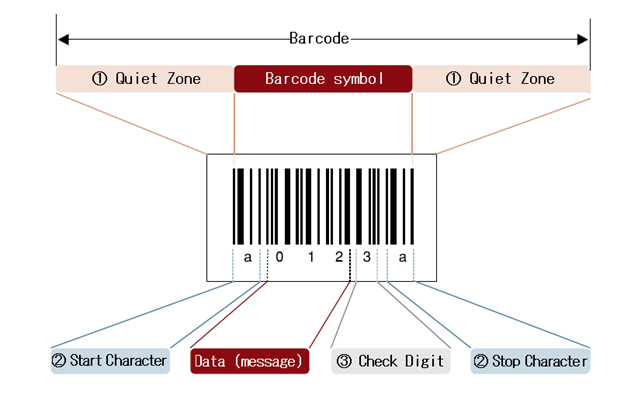

The diagram below shows the different elements of a UPC barcode, followed by an explanation of each component.

- Quiet Zone (margin)

The Quiet Zone is a blank margin located at either end of a barcode. The minimal margin between

Barcodes (distance from the outermost bar of one barcode to the outermost bar of another barcode) is 2.5 mm. If the width of a Quiet Zone is insufficient, barcodes are hard for a scanner to read.

2. Start Character/Stop Character

The Start Character and The Stop Character are characters representing the start and the end of the data respectively. The characters differ depending on the barcode type.

3. Check Digit

The Check Digit is a digit for checking whether the encoded barcode data are correct.

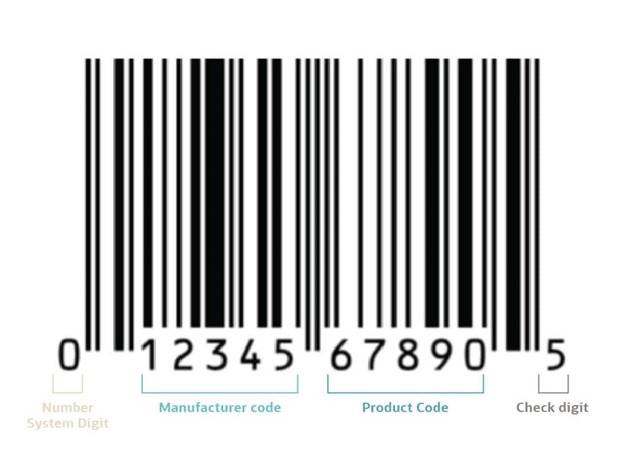

- Number system digit: The first digit represents the product category on UPC codes. For example, retail products often start with 0 or 1, pharmaceuticals with 3, and coupons with 5.

- Manufacturer code: The first group of characters after that initial number usually identify the manufacturer. GS1, a global standards organization that regulates UPCs, assigns each manufacturer a unique code.

- Product code: The next set of characters identify the specific product and is created by the manufacturer.

- Check digit: The check digit confirms the accuracy of the data tied to that barcode and flags any potential errors.

Common Product Codes

A standard format for barcodes does not exist. However, they do come with particular characteristics depending on how they are created. Companies developed a number of different types of barcodes as they became widely used over the last 50 years.

The following details summarize the most common barcode standards.

- UPC

Most UPCs have 12 digits, but some have only 7.

As noted earlier, this is one of the most ubiquitous barcodes. Most U.S. consumer products, from food to office supplies to home improvement goods, use UPC codes. Standard UPC barcodes have 12 digits, and short versions have seven digits.

- EAN

EAN barcodes are most often used in Europe.

EAN barcodes have much in common with UPC codes, with the key difference being they are widely used in Europe rather than America. They are also found on a wide variety of consumer goods. Standard EAN codes are 13 digits, while the shorter version has eight numbers.

- Code 39

This type is most often used by the DoD.

Code 39 barcodes can include numbers, letters and symbols and are primarily used by the U.S. Department of Defense and in certain manufacturing sectors, like automotive production.

- Code 128

You can find this barcode most in B2B, distribution, and transportation.

This is a more advanced version of Code 39, and got its name because Code 128 can include any of the 128 characters in ASCII. The ability to choose from a larger number of characters expands the amount and type of data that can be encoded. Code 128 is often used in B2B purchasing, distribution and transportation.

- Codabar (NW-7)

Codabar is no longer the leading type of barcode.

One of the earlier barcode formats, Codabar codes may include any number and the letters A-D. While no longer a leading type of barcode, certain libraries, blood banks and delivery services still use it.

- Interleaved 2 of 5

Interleaved 2 of 5 barcodes must have an even number of digits.

Interleaved 2 of 5 barcodes use only numbers and contain a high density of bars. The total number of digits must be even, so businesses will sometimes add a zero at the beginning. This type of code is common in warehousing and shipping, and also appears on some employer-issued badges.

- QR code

QR codes have become popular in sales and marketing.

Most people have used QR codes, or are at least familiar with them. Newer versions of smartphones can read these barcodes with their built-in cameras. Toyota invented QR codes in 1994, and today they can be used to direct consumers to a website, confirm a person’s identity on a login page or encrypt data. A QR code can encode more than 7,000 numbers or 4,000 letters.

- PDF417

This type is often used for driver’s licenses.

This is a 2D barcode that uses stacked linear rows and consists of anywhere from three to 90 rows. Each row is comparable to a basic linear barcode. You can find PDF417 barcodes on driver’s licenses and other ID cards, as well as in warehouses.

- Data matrix

Data matrix barcodes have robust error-checking capabilities

One other popular type of 2D barcode is a data matrix. This barcode can store not just alphanumeric characters, but files. Data matrix barcodes have robust error-checking capabilities, which allows scanners to still read these codes even when they have significant damage. Since the barcode can stand up to tough conditions, it’s often used on surgical tools, circuit boards, or electrical rating plates on appliances.

5 Ways to Use Barcodes

There are countless use cases for barcodes, and they can dramatically increase the efficiency and accuracy of your daily operations. Here are a few of their most popular uses:

- Tracking inventory:

Companies need to know not just their current inventory levels, but the location of those products, at all times. Barcodes can resolve that warehouse management issue. Warehouse associates scan new items as they arrive and again when they’re shipped out as part of an order in more automated facilities, mounted scanners might scan products as they move along a conveyor. Every SKU needs a barcode, of course, and codes must be linked to a database that has all the necessary product information. But once that’s set up, inventory numbers will always be reliable and updated in real-time.

- Tracking assets:

Barcodes are the most popular method for tracking the assets that businesses use to support their daily operations, like machinery, cars, and computers. Barcodes, paired with asset tracking software, help businesses monitor the status and location of those assets and store any relevant records about maintenance or repair. This is important because, unlike inventory, organizations often hold onto capital assets for years and use them repetitively. For mobile items like computers or vehicles, barcodes can show who last used those items and when. They also help company leaders understand the usage and condition of different assets as they plan future investments.

- Invoicing:

Many organizations put barcodes on invoices to make it easier to track accounts payable (AP) and accounts. Companies could put barcodes on invoices to tie them to a specific customer. When the customer pays, an employee can scan the barcode to make sure they credit the correct account and could follow the same process for AP debits. Invoice barcodes can also expedite the fulfillment process. A warehouse worker could print the invoice for an order, then scan the code to figure out which items to pick and where they’re located, reducing the chance of mistakes. Or the worker could scan the barcode after gathering all the items for an order to confirm the package contains all the correct items.

- Mail:

Much like with inventory, businesses can use barcodes to track all the mail and packages they send out. They can scan letters and packages before handing them off to couriers to link tracking information to that order, and then send it to customers so they can check the status of their orders. If mail is returned to the seller, it can scan the barcode to quickly identify the customer it needs to contact to resolve the issue.

- Mail Merges:

A mail merge links a data source, like a spreadsheet, with another document to automatically plug that data into preset fields. Businesses can use mail merges to create barcodes for a batch of items in a few simple steps. It’s a much more efficient method than handling them one by one.

*Ref.: DENSO WAVE INCORPORATED.

https://www.densowave.com/en/adcd/fundamental/barcode/barcode/index.html

ORACLE NETSUITE.

https://www.netsuite.com/portal/resource/articles/inventory-management/barcode.shtml